What is Chipless RFID?

Chipless RFID is a type of Radio Frequency Identification technology that works without the need for a microchip. Unlike traditional RFID systems, where a silicon microchip in the tag stores data, chipless RFID relies on unique patterns or materials to encode information. These tags are often printed using conductive inks or made with specific materials that can reflect radio waves in a unique way, acting as a signature to identify items.

In simpler terms, chipless RFID is like a barcode but more advanced, as it doesn’t need physical scanning with direct contact. Instead, it uses radio waves, allowing for faster and more efficient item tracking and identification.

How Does Chipless RFID Work?

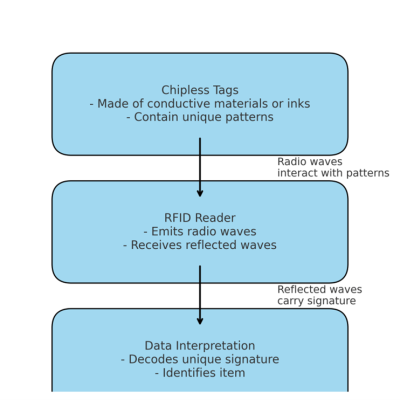

At its core, chipless RFID operates on the principle of electromagnetic wave interaction.

-

Chipless Tags :

The tags are designed using materials like conductive polymers, metals, or specialized inks. These tags are printed or embedded with unique patterns that interact with radio waves.

-

RFID Reader :

The reader emits radio waves, which hit the tag. When these waves interact with the tag’s material or pattern, they are reflected back in a specific way.

-

Data Interpretation :

The reflected radio waves carry the tag's unique pattern/signature, which is then decoded by the reader using software. This allows the system to identify the item the tag is attached to.

Unlike traditional RFID, which uses microchips to actively store and process data, chipless RFID relies entirely on the physical properties of the tag to generate unique signals.

Key Difference from Traditional RFID :

In traditional RFID, a microchip on the tag processes and stores information. In chipless RFID, the physical properties of the tag (its design or materials) create the unique response to the radio waves. This eliminates the need for a chip but still allows the tag to carry information.

Why Chipless RFID is a Big Deal

Chipless RFID addresses several limitations of traditional RFID systems. For one, manufacturing silicon microchips can be expensive, especially for large-scale deployments like tracking millions of items in retail or logistics. Chipless RFID eliminates the chip, making it much cheaper to produce than chip-based RFID tags. , They are more environmental friendly Since it can be made from recyclable or biodegradable materials.They are also very versatile s they can be printed on paper, fabric, or plastic, making them useful for various industries.

Features of Chipless RFID :

-

No Electronics Needed :

Chipless RFID tags eliminate the need for power sources, batteries, or microchips. Instead, the data is embedded directly into the design or material of the tag.

-

Printable and Lightweight :

These tags can be printed using conductive inks on materials like paper, packaging, or labels. This makes them lightweight, flexible, and easy to integrate into a variety of products.

-

Bulk Scanning :

Similar to traditional RFID, chipless RFID enables high-speed, bulk scanning without requiring a direct line-of-sight, offering a significant advantage over barcodes.

-

Durability :

With no electronic components, chipless tags are highly resistant to physical damage, ensuring longer usability even in harsh environments.

Applications of Chipless RFID :

Chipless RFID is gaining widespread attention for its cost-effectiveness and ease of use. Its versatility has made it a valuable tool in various industries. Here are some of its notable applications:

Low cost Retail and Inventory Management :

Chipless RFID offers a cost-effective alternative for tracking products on shelves and in warehouses. Unlike traditional RFID, chipless tags do not require expensive microchips or electronic components, significantly reducing implementation costs. Retailers can still monitor stock levels in real-time, ensuring accurate inventory management while avoiding the high upfront and maintenance costs associated with chip-based systems. This makes chipless RFID especially attractive for low-cost products and industries with tight margins.

Banking and Security :

Chipless RFID offers a more affordable and scalable solution for embedding security features in cheques and other banking instruments. These tags provide quick and reliable verification, ensuring that fraud prevention measures are maintained without the added expense of chip-based systems. This is really useful for high-volume financial transactions.

Healthcare :

Chipless RFID can be used to track disposable medical supplies like syringes, bandages, and patient records, providing a simple yet effective solution. Since chipless RFID doesn't require microchips, it can be integrated directly into the packaging or labels of medical items. This helps hospitals monitor the usage of supplies in real-time, ensuring that items like bandages or syringes are replenished before they run out. Moreover, the absence of electronic components makes chipless tags more durable and resistant to physical wear, ensuring the reliability of tracking in healthcare environments.

Environmental and Waste Management :

Chipless RFID, especially when made from eco-friendly materials, plays a key role in improving waste management and recycling practices. These tags can be used to track waste items and facilitate sorting by providing a simple, efficient way to label and categorize materials. Since chipless RFID does not rely on electronic components, it is often more suitable for environmentally-conscious applications, where minimizing electronic waste is important. By integrating chipless RFID into waste management systems, organizations can enhance recycling accuracy, reduce contamination, and support sustainable waste processing practices.

Aviation and Chipless RFID :

Airlines are using chipless RFID for cost-effective and sustainable luggage tracking. These tags provide real-time updates on baggage location, helping reduce lost luggage incidents and improving overall handling of passenger baggage. Designed to be durable and lightweight, chipless RFID tags can withstand the rigors of air travel and integrate into existing airport systems. Their eco-friendly nature also supports airlines' efforts to minimize electronic waste while managing high passenger volumes and reducing delays. By simplifying logistics and tracking accuracy, chipless RFID greatly eases baggage handling process in aviation.

Challenges with Chipless RFID :

Despite its many benefits, chipless RFID has some limitations :

- Lower Data Capacity : Unlike traditional RFID, which can store larger amounts of data, chipless RFID typically stores minimal information.

- Shorter Read Range : Readers may need to be closer to chipless tags to detect them accurately.

- Complex Manufacturing : Creating precise patterns or using conductive inks requires advanced techniques.

- Interference Issues : External factors like metal surfaces or water can affect performance.

How to overcome these Challenges :

- Using advanced encoding techniques to maximize the information that can be stored on chipless tags. Combining chipless RFID with other identification methods, like barcodes or QR codes, can also supplement data storage needs.

- Developing more sensitive readers and antennas capable of detecting weaker signals from chipless RFID tags. Optimizing the design and placement of tags can also improve the read range.

- Invest in scalable production technologies, such as roll-to-roll printing or advanced nanotechnology, to simplify the creation of chipless RFID tags. Researching alternative materials, like cost-effective conductive inks, can further streamline manufacturing.

- Design tags with materials resistant to interference from metal and water. For instance, incorporating protective layers or using substrates that minimize signal distortion can improve performance. Additionally, calibrating readers to account for environmental factors can enhance detection accuracy. By focusing on these strategies, chipless RFID can overcome its challenges and unlock its potential for widespread, cost-effective use across various industries.

Conclusion :

Chipless RFID represents a much needed advancement in tracking technology. By eliminating the need for microchips, it offers an affordable, eco-friendly, and versatile solution for industries worldwide. While it’s not without challenges, the potential for growth and innovation in this field is really high.